Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: NHG

Packaging: Wooden Cases

Productivity: 500 /Year

Transportation: Ocean,Land,Air

Place of Origin: PRC

Supply Ability: 500

Port: DALIAN SEAPORT,TIANJIN SEAPORT,SHANGHAI SEAPORT

Payment Type: L/C,T/T

Incoterm: FOB,CIF

Bolting Jumbo for Coal Mine

This jumbo drilling rig With automatic hole collaring and percussion shutdown function after the drilling procedure completed plus 3 seconds delay to flush the hole bottom, the rig returns automatically to start mode. With AUTO shutdown protection function of the drifter and the rock drill tools, the rig will lubricate the drifter when rock drilling idle and when water flushing on. Advanced combo automatic anti-jamming system can adjust the rotation, feed and percussion pressure automatically according to the rock condition to ensure rock drilling operation always in optimum mode.

This hydraulic underground jumbo drilling rig With high pressure and closed cycle hydraulic system to drive four wheels, possible for two speed trans.mission while moving forward and backward. With engine's non-stop function when overloaded and climbing slopes, the rig will automatically adjust to lower speed with higher torque output. The two loop cicuitry pedal braking system plus emergency braking device can ensure tramming safety. With only width of 1.65 m of ultra-narrow articulated heavy duty chassis design, the minimum turning radius is 2.8m with 14 degree climbility and tramming speed up to 12 km/h and the rig aims to drill blast holes in underground mines and tunneling excavation as well as bolting operation with professional narrow design in mind.

I. Technology Introduction

Bolt jumbo support is a fast, safe and economical way to support coal mine roadways. This support method is widely used in major coal producing countries at home and abroad. The bolt support rate in foreign advanced coal mining countries often exceeds 80%.

In modern high-yield and high-efficiency mines, Continuous Miners and subsequent supporting equipment have become important roadway excavation equipment. Continuous miners are mostly used in room or room and pillar mining, and double or multi-lane rapid excavation, with high output and fast lane formation speed. Since the goaf roadway needs timely support, the bolt drill carriage is particularly important among the supporting equipment of the Continuous Miner.

II. Performance Characteristics

ADVANTAGES OF BOLT JUMBO EQUIPMENT

· Our products and equipment were originally designed for the mine: they are robust, without unnecessary sophistications, easy to use and maintenance.

· In order to reconcile competitiveness and performance, these devices are based on a constructive system of customized as standard!

· A team of engineers, technicians, hydraulic engineers and fitters provide design, development, assembly and start-up equipment on site in the world.

Technical Parameter

| Location | Basic performance | unit | CMM2-12 | CMM2-15 | CMM2-16 | CMM2-18 | |

| Machine parameters | Dimensions | long | mm | 5900 | 5900 | 5900 | 5900 |

| width | mm | 1250 | 1250 | 1250 | 1250 | ||

| high | mm | 2190 | 2190 | 2190 | 2190 | ||

| Adapt to the roadway section | m² | 12 | 15 | 16 | 18 | ||

| Working range (width X height) | mm | 4600X2800 | 4500X3500 | 4600X3600 | 5000X3600 | ||

| Anchor rod and cable hole diameter | mm | Φ27-Φ32 | |||||

| Depth of anchor rod and anchor cable hole | m | 0-18 | |||||

| Drill rod specifications | mm | B19、B22 | |||||

| Total Weight | Kg | 10000 | 10800 | 10800 | 11000 | ||

| Slewing mechanism | Type characteristics | Hydraulic motor rotary | |||||

| Rated output torque | N.m | 300(17MPa) | |||||

| Rated speed | r/min | 550 | |||||

| Work flow | L/min | 80 | |||||

| Thruster | Propulsion method | Hydraulic cylinder + chain | |||||

| Advance itinerary | mm | 1600 | |||||

| Maximum feed force | KN | 15 | |||||

| Advancing speed | mm/min | 5000 | |||||

| Vertical flip angle | (°) | 270 | |||||

| Horizontal rotation angle | (°) | 180 | |||||

| Boom mechanism | Telescopic length | mm | 1190 | ||||

| Swing arm (inside and outside) | (°) | 20.4 | |||||

| Up/down | (°) | Oct-55 | |||||

| Propeller swing drive | Hydraulic screw swing cylinder | ||||||

| Walking mechanism | Walking speed | m/min | 0-15 | ||||

| Gradeability | (°) | ±15 | |||||

| Track width | mm | 350 | |||||

| Ground clearance | mm | 300 | |||||

| Ground pressure | MPa | 0.1 | |||||

| Electrical System | Total power | kw | 45 | ||||

| Supply voltage | V/AC | 660/1140 | |||||

| Rated speed | r/min | 1480 | |||||

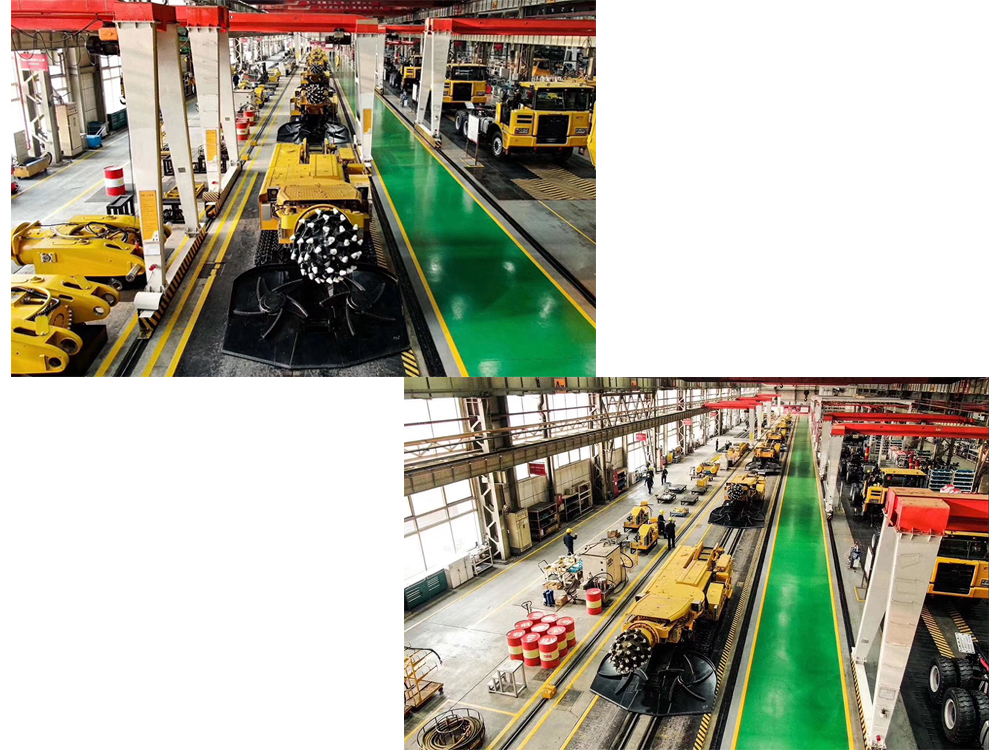

Our Company

North Heavy Gryps Group (hereinafter referred to as NHG) was established in 1993. The company is headquartered in Shenyang Economic & Technological Development Zone which is honored by the State Department as “ Double Demonstration Zone” of national equipment manufacturing industry. NHG is specialized in the R&D, manufacturing and sales of mining and tunneling equipment and overseas mining and tunneling engineering services with more than 3,000 employees (including construction personnel) worldwide, 2,000 equipment and 300 construction projects providing services to different customers in more than 10 countries all over the world.

The company has established branches and offices in Southeast Asia (Laos), South Asia (India), Europe (Poland, Turkey), Russian (Novokuznetsk), South America (Venezuela), Africa (South Africa) and other countries. A regional operation network with equipment sales, service and parts supply and engineering construction has been established. The 24 × 365 service is implemented to meet the user's requirements to the greatest extent.

With the rapid development of NHG, adhering to the tenet of “QUATLITY WINS WORLD, TECHNOLOGY BUILDS NHG”, it is standing out as a pioneer in the industry and has become an international benchmark enterprise in China both for international sales of mining & Tunneling Machinery and also for international engineering construction services.

Product Categories : Coal Mining Machinery > Bolting Jumbo

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.