Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: ML360A

Brand: NHG

Cutting Motor Power(kw): 2*180

Pump Motor Power(kw): 75

Supply Voltage(v): 1140

Electrical Control: EPEC

Packaging: Wooden Cases

Productivity: 500 /Year

Transportation: Ocean,Land,Air

Place of Origin: PRC

Supply Ability: 500

Port: DALIAN SEAPORT,TIANJIN SEAPORT,SHANGHAI SEAPORT

Payment Type: L/C,T/T

Incoterm: FOB,CIF

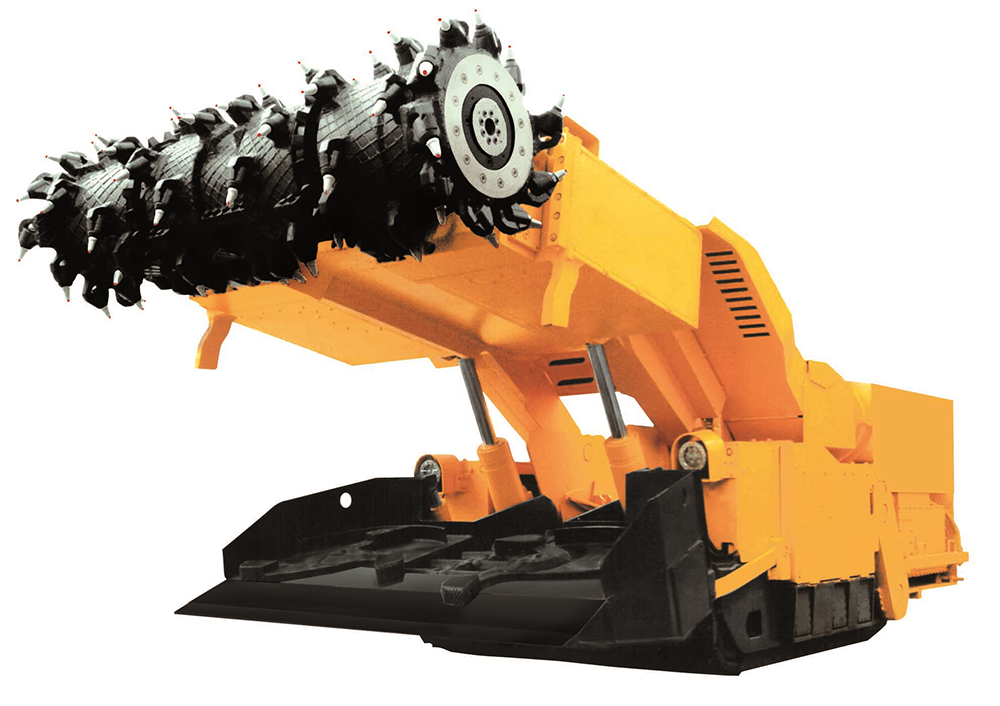

Tunnel Mining Continuous Miner

A machine with a large rotating steel drum equipped with tungsten carbide teeth that scrape coal from the seam. Operating in a “room and pillar” system – where the mine is divided into a series of 20-to-30 foot “rooms” or work areas cut into the coalbed – it can mine as much as five tons of coal a minute – more than a miner of the 1920s would produce in an entire day. Continuous Miners account for about 45% of underground coal production, and also utilize conveyors to transport the removed coal from the seam. Remote controlled continuous miners are used to work in a variety of difficult seams and conditions and robotic versions controlled by computers are becoming increasingly common.

Product Features:

Strong cutting ability

The core technology of pick arrangement realizes the optimal design of pick arrangement under different working conditions, improves cutting efficiency, reduces pick consumption, and realizes large cutting depth and high efficiency cutting.

Wide range of applications

The cutting range covers 1.8-4.5/2.4-5.1 meters, which can be applied to more than 70% of coal mine roadways. With strong climbing ability, it can be applied to coal mine roadways with a slope of ±17°.

High reliability

The whole machine adopts the design concept of high safety factor, and the service life of key parts such as reducer can reach more than 10,000 hours.

Cutting system protection technology

There is a patented "Adjustable Heart Torque Limiting Device" protection device between the cutting and the reducer, which effectively protects the machine from the impact and vibration of the cutting overload and reduces the working noise.

Strong loading and transportation ability

Create a precedent in the industry and adopt innovative design of shovel, transport and separate drive. The power is large, the efficiency is high, the material can be transported out quickly, the maintenance is easy, and the service life of the driving parts of the scraper is improved.

High dispatch efficiency

The walking frequency conversion drive realizes stepless speed regulation, and automatically adjusts according to the actual working conditions, so as to achieve the purpose of powerful work cutting and fast transportation speed.

Continuous Miner ML360A

| Adaptation capacity | |

| Cut range(m) | 1.8~4.5/2.4~5.1 |

| Grading ability(°) | ±17 |

| Cutting Hardness | ≤40MPa coal ≤80MPa with gangue |

| Work slope(°) | ±12 |

| Cutting head rotation speed (r pm) | 49 |

| Dinting depth (mm) | 205 |

| Walking speed(m/min) | 0-18 |

| Star wheel speed(r pm) | 47 |

| Hydraulic Parameter | |

| External spray water (Mpa) | 1.0-3.0 |

| Water volume (L/min) | ≥120 |

| Tank volume (L) | 850 |

| System pressure (Mpa) | 25 |

| Key parameters of the machine | ||

| Total Weight(t) | 95 | |

| Dimensions | Length (mm) | 11900 |

|

| Width (mm) | 365 |

|

| Height (mm) | 1630 |

| Machine total power (kw) | 763 | |

| Type of transport | Middle chain scraper chain | |

| Transport chute dimension (mm) | 746*350 | |

| Width of crawler | 650 | |

| Dust removal from | Airborne wet dust collector + External spray | |

Our Company

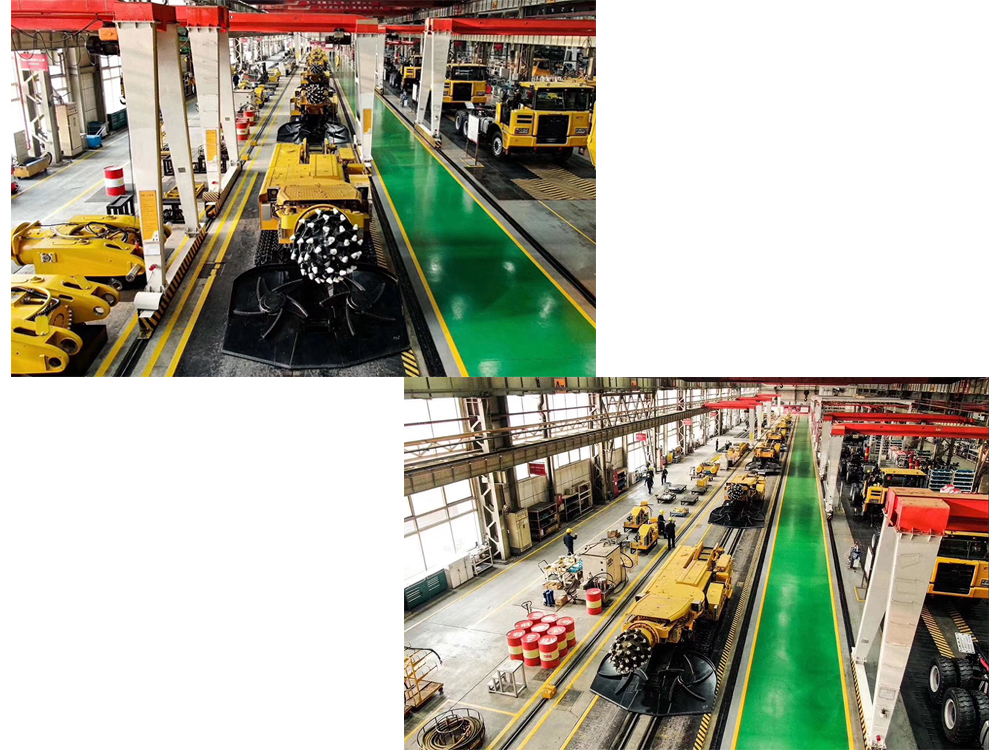

North Heavy Gryps Group (hereinafter referred to as NHG) was established in 1993. The company is headquartered in Shenyang Economic & Technological Development Zone which is honored by the State Department as “ Double Demonstration Zone” of national equipment manufacturing industry. NHG is specialized in the R&D, manufacturing and sales of mining and tunneling equipment and overseas mining and tunneling engineering services with more than 3,000 employees (including construction personnel) worldwide, 2,000 equipment and 300 construction projects providing services to different customers in more than 10 countries all over the world.

The company has established branches and offices in Southeast Asia (Laos), South Asia (India), Europe (Poland, Turkey), Russian (Novokuznetsk), South America (Venezuela), Africa (South Africa) and other countries. A regional operation network with equipment sales, service and parts supply and engineering construction has been established. The 24 × 365 service is implemented to meet the user's requirements to the greatest extent.

With the rapid development of NHG, adhering to the tenet of “QUATLITY WINS WORLD, TECHNOLOGY BUILDS NHG”, it is standing out as a pioneer in the industry and has become an international benchmark enterprise in China both for international sales of mining & Tunneling Machinery and also for international engineering construction services.

Product Categories : Coal Mining Machinery > Continuous Miner

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.