Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: NHG

Packaging: Wooden Cases

Productivity: 500 /Year

Transportation: Ocean,Land,Air

Place of Origin: PRC

Supply Ability: 500

Port: DALIAN SEAPORT,TIANJIN SEAPORT,SHANGHAI SEAPORT

Payment Type: L/C,T/T

Incoterm: FOB,CIF

Portable Diesel Anchor Drilling Rig

The drilling rig is a crawler chassis loading, full hydraulic drive, power head drilling rig. It is a general-purpose drilling equipment suitable for vertical or inclined drilling. It is applicable to a variety of different drilling processes, so it has a variety of formations and complex working conditions. The large adaptability can effectively solve the problem of difficult hole formation when drilling in loosely covered formations, cobblestone layers, and broken bedrock formations, and has a very wide range of uses.

Mainly suitable for the construction of deep foundation pit support, foundation reinforcement engineering and ground source heat pump holes of high-rise buildings, and also for the construction of large-tonnage prestressed anchor holes and drainage holes in rock engineering such as hydropower projects, railways, highway slopes, etc. Engineering; cobblestone stratum high-pressure rotary jet pilot hole engineering, and blasting engineering construction. It can also be applied to anti-floating anchoring, interior building foundation reinforcement, rotary jet reinforcement, subgrade dam foundation reinforcement, landslide prevention, open quarry blasting, tunnel pipe sheds and other projects.

Our company has always operated with the philosophy of designing custom machines detailed to customers’ requirements. Furthermore, the company maintains its focus on safety, reliability, ergonomics and efficiency while building on previous designs. Given the customer’s desire for a semi-automatic drilling system, we decided to start with our existing four-head roof bolter design and see how it could be expanded to a Drilling And Bolting Machine to meet the customer’s needs.

Advantages:

• Has a strong climbing ability and adaptive to the rough pavement

• Adapt to a wide range, can be furnished with various types of DTH impactor, can drill different diameter and different depth in variety of position and angle

• Also can be furnished with dry or wet dust collector when working, effectively reduce dust pollution to the environment, and protect the worker

• Anti-jamming system, safety operation.

• Crawler type undercarriage with track oscillation system.

• Yuchai turbo charged diesel engines

• Efficient screw high pressure compressors

• Single section boom system.

• Hydraulic cylinder operated feed system mounted in an steel feeed beam

performance parameters

| Serial number | Content | parameter | Remarks |

| Machine Parameters | Overall dimensions(L×B×H)(m) | 8×2.65×3.6 |

|

|

| Total Weight(t) | 28 |

|

|

| Working range of positioning drilling(m) | 6.8×4.7 |

|

|

| Gradeability(%) | 25 |

|

| Blasthole Drill boom | Rock drill | PD350 |

|

|

| Blast hole diameter (mm) / maximum depth (m) | φ38-45/3.0 |

|

|

| Number of booms (pieces) | 2 |

|

|

| Up and down lifting angle (°) | -15--+60 |

|

|

| Swing angle from left to right (°) | ±35 |

|

|

| Pitch angle(°) | -6--+90 |

|

|

| Single penetration depth(m) | 3.0 |

|

|

| way to control | Manual |

|

|

| Propulsion(kN) | 10 |

|

| Anchor rod Drill boom | Anchor hole diameter (mm)/depth (m) | Φ28-Φ32/1.6-8.0 | Manual extension |

|

| Number of anchor arms (a) | 1 |

|

|

| Up and down lifting angle (°) | -15--+60 |

|

|

| Swing angle from left to right (°) | ±35 |

|

|

| Pitch angle (°) | -6--+90 |

|

|

| Single penetration depth (m) | 1.6/2.4. |

|

|

| way to control | remote control |

|

|

| Propulsion force (kN) | 10 |

|

| Hydraulic system | Hydraulic oil tank volume (L) | 600 |

|

|

| cooling method | Water cooling |

|

| Chassis | Gradeability(%) | 25 |

|

|

| Walking speed (km/h) | 14 |

|

|

| Ground clearance | 380 |

|

|

| Model/number of front and rear tires | 12.00-20-24 T900 |

|

|

| engine model | QSB4.5-C160 |

|

|

| Engine power (kW) | 120/2200 |

|

|

| Engine emissions | Tier3 |

|

|

| Engine manufacturer | Dongfeng Cummins |

|

|

| Braking method | Normally closed wet brake |

|

|

| Front and rear axle models | DANA213 |

|

|

| Way of walking | Four-wheel steering/four-wheel drive |

|

|

| Fuel tank (L) | 110 |

|

| electric system | Rated current (A) | 67.4/116.7 |

|

|

| Supply voltage (V) | AC380 |

|

|

| Rated speed (r/min) | 1480 |

|

| water system | Booster pump model/manufacturer | CDLF8-12 |

|

|

| Motor power (kW) | 4 |

|

|

| Rated displacement (L/min) | 100 |

|

|

| Pressure (bar) | 8 |

|

| Air system | Air compressor model | GCUIC-110900 |

|

|

| Displacement (L/min) | 1200 |

|

|

| Motor power (kW) | 11 |

|

| Anchor guard platform | Supporting platform size (L×B×H) (m) | 1.2×0.75×1.2 | Can accommodate two people at the same time |

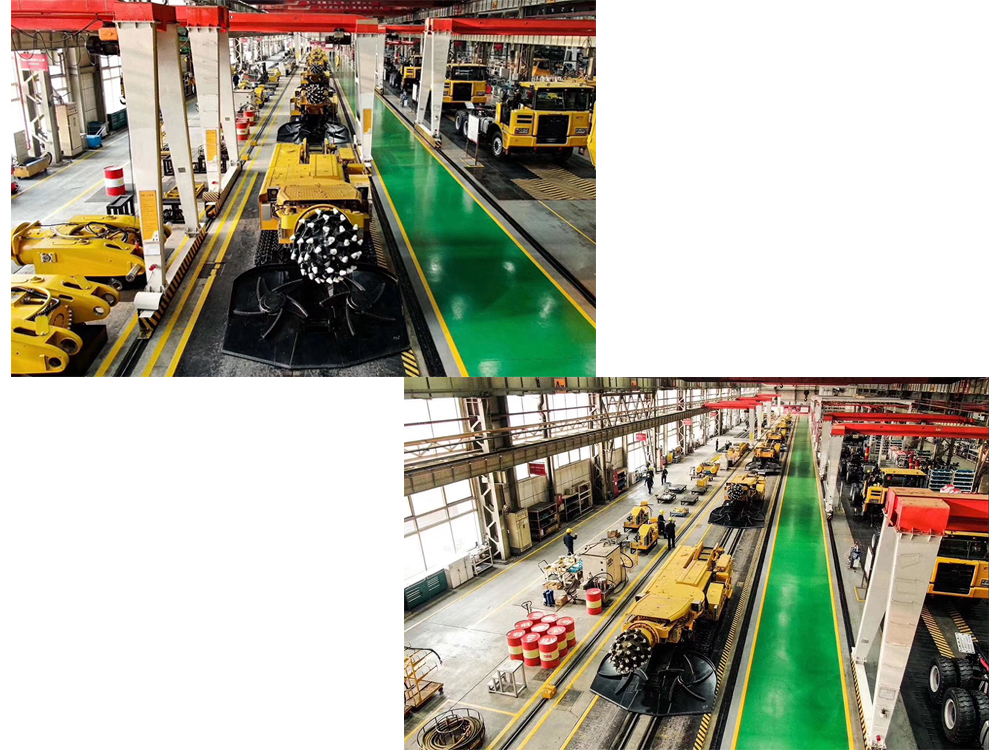

Our Company

North Heavy Gryps Group (hereinafter referred to as NHG) was established in 1993. The company is headquartered in Shenyang Economic & Technological Development Zone which is honored by the State Department as “ Double Demonstration Zone” of national equipment manufacturing industry. NHG is specialized in the R&D, manufacturing and sales of mining and tunneling equipment and overseas mining and tunneling engineering services with more than 3,000 employees (including construction personnel) worldwide, 2,000 equipment and 300 construction projects providing services to different customers in more than 10 countries all over the world.

The company has established branches and offices in Southeast Asia (Laos), South Asia (India), Europe (Poland, Turkey), Russian (Novokuznetsk), South America (Venezuela), Africa (South Africa) and other countries. A regional operation network with equipment sales, service and parts supply and engineering construction has been established. The 24 × 365 service is implemented to meet the user's requirements to the greatest extent.

With the rapid development of NHG, adhering to the tenet of “QUATLITY WINS WORLD, TECHNOLOGY BUILDS NHG”, it is standing out as a pioneer in the industry and has become an international benchmark enterprise in China both for international sales of mining & Tunneling Machinery and also for international engineering construction services.

Product Categories : Coal Mining Machinery > Drilling And Bolting Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.