Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: NMJ2-25

Brand: NHG

Packaging: Wooden Cases

Productivity: 500 /Year

Transportation: Ocean,Land,Air

Place of Origin: PRC

Supply Ability: 500

Port: DALIAN SEAPORT,TIANJIN SEAPORT,SHANGHAI SEAPORT

Payment Type: L/C,T/T

Incoterm: FOB,CIF

Crawler Double-arm Tunneling Jumbo

The self-developed NMJ2-25 crawler double-arm tunneling jumbo is used for blasting holes and bolt holes in tunnels and tunnels in coal mines and metal mines. Workers stand in a safe place to operate a mechanical arm for rock drilling. This equipment replaces the previous manual hand-held air gun drilling operation, reducing the work intensity of workers, improving work efficiency and safety factor. Suitable for section (width x height) 3.Om x3.0m to 5.9mx4.3m. Climbing ≤14°, walking speed up to 2.4km/h. The working mechanism of the machine adopts full hydraulic drive, and the rock drilling speed can reach 0.8-2m/min. The working mechanism of this machine adopts full hydraulic drive, which is flexible and fast in rock drilling speed; advanced hydraulic system, convenient maintenance; stable work and climbing ability Strong, easy to operate, safe and reliable.

Advantages

Advanced, user-friendly control system

Automatic boom movements, pre-planned drilling patterns and data collection offer productivity control

Noise and vibration-insulated cabin offers comfort and excellent visibility

RD525 series rock drills deliver superior performance with high consumable life

Dynamic correcting redirects drilling during boom movement and helps keeping the hole bottom in place

Lock-to-target: Helps finding the hole position quickly and accurately

Main Technical Parameters

|

| Project | Unit | NMJ2-25 |

| Complete Machine | Dimensions (Length ×width× height) | mm | 10120×1200×1380 (Ceiling height 2455) |

| Adapt to section (Width× height) | m | 3.0×3.0-5.9×4.3 | |

| Drilling diameter | mm | Φ38-Φ76 | |

| Drilling length | mm | 2475/3090 | |

| Drilling depth | mm | 2100/2700 | |

| Drilling speed | m/min | 0.8-2 | |

| Total Weight | Kg | 13000 | |

| Cable drum capacity | m | >70 | |

| Hydraulic oil tank volume | L | 340 | |

| Drill boom | Up/down | (°) | 45/20 |

| Swing arm (left and right) | (°) | ±36 | |

| Thruster | Pitch/tilt | (°) | 95/3 |

| Advance compensation | mm | 1550 | |

| Axial rotation | (°) | ±180 | |

| Swing angle (inside/outside) | (°) | 14/36 | |

| Chassis | Turning radius | mm | ≥5.3 |

| Walking speed | km/h | 2.4 | |

| Grade ability | (°) | ≤14 | |

| Ground clearance | mm | 195 | |

| Rock drill model | Model |

| HYD200/HC28(Optional) |

| Gas supply system | Air pump motor power | KW | 2.2 |

| Air pressure for rock drill | Mpa | 0.4 | |

| Water supply system | Water pump motor power | KW | 2.2 |

| Water pressure for rock drill | Mpa | 0.8 | |

| Water pressure for cooler | Mpa | 0.6 | |

| Electrical System | main motor power | KW | 75 |

| Supply voltage | V | 380/660/1140 | |

| Motor speed | r/min | 1470/2840/2840 |

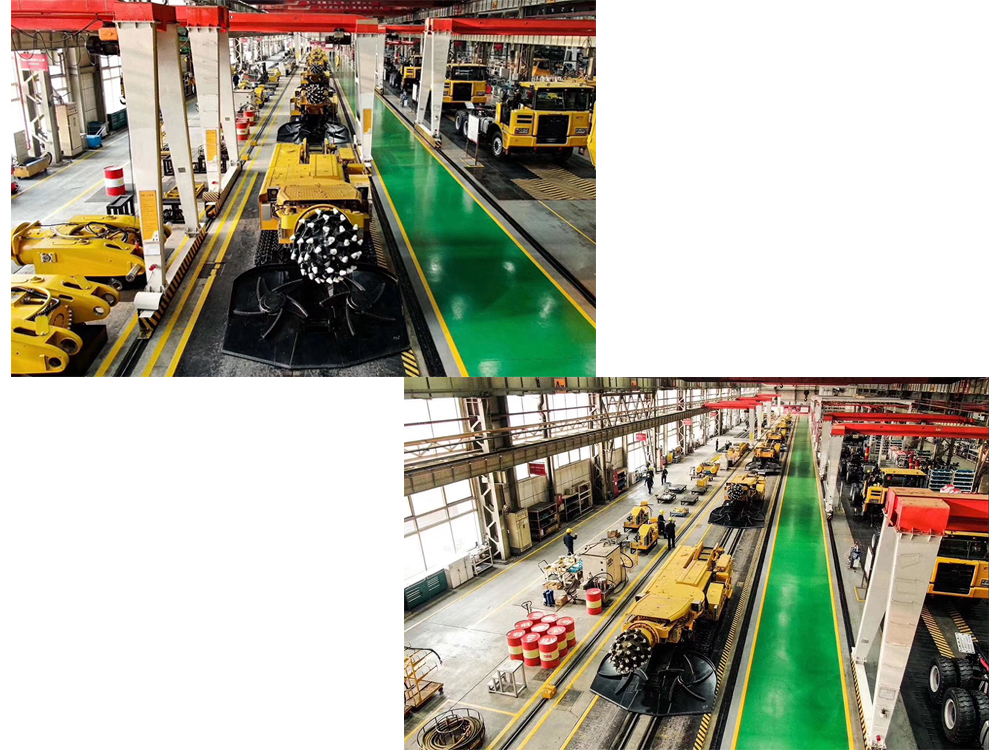

Our Company

North Heavy Gryps Equipment And Engineering Co., Ltd. (hereinafter referred to as NHG) was established in 2013. The company is headquartered in Shenyang Economic & Technological Development Zone which is honored by the State Department as [ Two Modeling Park" of national equipment manufacturing. As the chief company of North.T, NHG is specialized in the R&D, manufacturing and sales of mining and tunneling equipment with more than 2000 employees (including construction personnel) worldwide, more than 2,000 equipment and more than 300 construction projects providing services to different customers in more than 10 countries around the world.

The company has established branches and offices in Southeast Asia (Laos), South Asia (India), West Asia (Turkey), Russian (Russia), South America (Venezuela), Africa (South Africa) and other countries. A regional operation network with equipment sales, service and parts supply, engineering construction and freight forwarding has been established. The 24 × 365 service is implemented to meet the user's requirements to the greatest extent.

Product Categories : Tunneling Jumbo

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.