Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: NTR323

Brand: NHG

Packaging: Wooden Cases

Productivity: 500 /Year

Transportation: Ocean,Land,Air

Place of Origin: PRC

Supply Ability: 500

Port: DALIAN SEAPORT,TIANJIN SEAPORT,SHANGHAI SEAPORT

Payment Type: L/C,T/T

Incoterm: FOB,CIF

Tunneling Roadheader Machine Underground Working

The Roadheader is a continuous mining and tunneling machine that can economically excavate a wide range of rocks. The Road Header can be used for building mine entrances, galleries, tunnels and for mining coal and ore.

The Tunneling Roadheader does require a greater investment than an excavator with a roadheader attachment. The excavator’s performance, however, is limited because it is dependent on the hydraulic power capabilities of the excavator. Attachments are extremely flexible in large tunnels for scaling, cutting manholes, corners and excessive grouting. A disadvantage of using an excavator with roadheading attachments is its inability to remove muck simultaneous to cutting; it must be stopped and moved in order to clear muck, which results in a reduced production rate, which includes cutting the material as well as moving it behind the machine.

Suitable for the tunnengling of coal tunnels and mixed coal-rock tunnels construction, also can be used in the tunneling of railway, highway and water projects.

Product Features:

1. Large positioning and cutting range and optimal machine stability.

2. The optimized cutting head arrangement of cutting heads makes the cutting forces more stable and the impact smaller, the cutting efficiency is increased by 20%, and the cutting consumption is reduced by 20%.

3. The flexible connection technology is adopted between the cutting motor and the cutting reducer, which has eccentric compatibility, which solves the problem of eccentric damage to the reducer and the motor due to rigid connection.

4. The cutting head, shovel board, first transport and other parts that are most prone to wear use high-strength composite wear-resistant plates, which have a life span more than ten times that of ordinary steel plates.

5. The receiving device adopts multiple anti-seize measures:

6. The design of the dual cooling system of the hydraulic system and wind water can ensure that the oil temperature of the hydraulic system is below 70 ° C, which can meet the long-term continuous cutting operation.

7. variable pump system, using load-sensitive multi-way valve, the hydraulic system generates less heat and improves the service life of seals.

8. The cutting motor self-circulating cooling system is innovatively configured to ensure that the equipment can still work normally without receiving external water.

9. Intelligent and safe electronic control system

10. Large air volume airborne dust removal system, environmental dust removal efficiency> 90%

Specification

| Item | NTR323 | ||

| Total weight(dedusting and 2nd conveyor included) | 132.5t | ||

| Dimension | L (2nd Conveyor not included/included) | 16.2/23.5m | |

|

| W | 4.0m | |

|

| H | 4.3m | |

| Total Power | 633KW | ||

| Maximum compressive strength of single cutting rock | 100MPa | ||

|

| L | 8m | |

|

| H | 7.5m | |

| Track width | 3.6m | ||

| Grounding pressure | 0.18MPa | ||

| Grading ability | ±16° | ||

| Power supply | AC1140V | ||

| Total cooling water demand | 0-150L/min | ||

| Required transformer capacity | 1000KVA | ||

Our Company

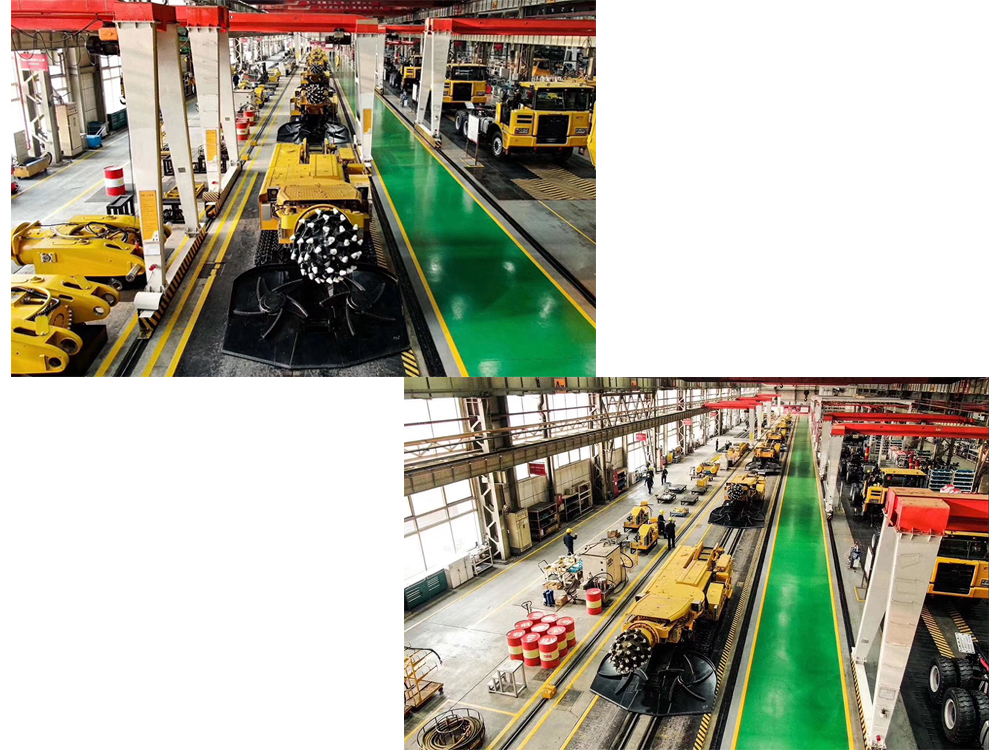

North Heavy Gryps Group (hereinafter referred to as NHG) was established in 1993. The company is headquartered in Shenyang Economic & Technological Development Zone which is honored by the State Department as “ Double Demonstration Zone” of national equipment manufacturing industry. NHG is specialized in the R&D, manufacturing and sales of mining and tunneling equipment and overseas mining and tunneling engineering services with more than 3,000 employees (including construction personnel) worldwide, 2,000 equipment and 300 construction projects providing services to different customers in more than 10 countries all over the world.

The company has established branches and offices in Southeast Asia (Laos), South Asia (India), Europe (Poland, Turkey), Russian (Novokuznetsk), South America (Venezuela), Africa (South Africa) and other countries. A regional operation network with equipment sales, service and parts supply and engineering construction has been established. The 24 × 365 service is implemented to meet the user's requirements to the greatest extent.

With the rapid development of NHG, adhering to the tenet of “QUATLITY WINS WORLD, TECHNOLOGY BUILDS NHG”, it is standing out as a pioneer in the industry and has become an international benchmark enterprise in China both for international sales of mining & Tunneling Machinery and also for international engineering construction services.

Product Categories : Roadheader for Tunneling

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.